Small to medium-sized businesses must pay careful attention to their monthly expenditures, ensuring that they are not exceeding their allowed budget. Like with any smaller or newly launched operation, money can be tight, which is why business leaders are constantly looking for ways to cut costs without losing valuable business.

No company wants to resort to cutting employees in order to improve profit margins. To avoid this painful situation, enterprises can turn to their own products and inventory management to find new ways of improving productivity and marketplace desirability. One of the largest sources of lost time is in relation to product tracking. Inventory is lost or misplaced through human error during manual data entry. Avoid costly inventory management mistakes and invest in labeling technology.

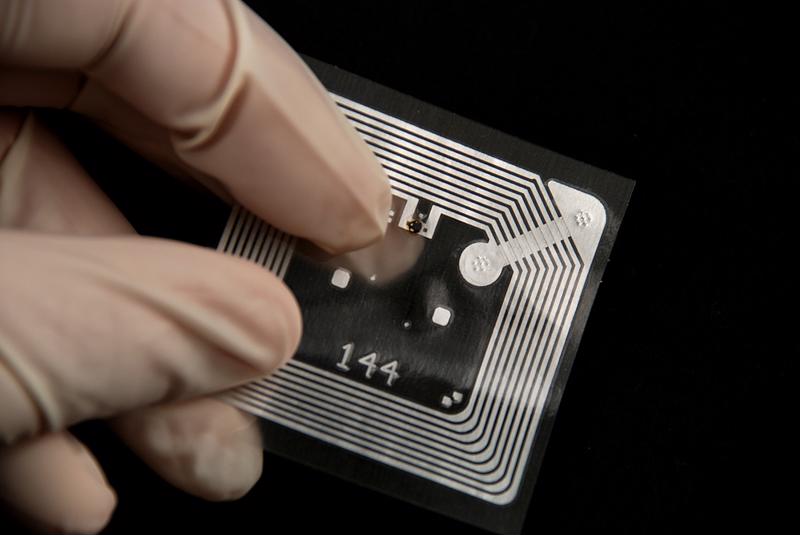

Barcodes or RFID tags?

Radio frequency identification tags provide manufacturers and retailers a way to track their inventory without resorting to manual data entry. Essentially, these tags contain a small chip with product data, which sends information wirelessly to a RFID reader. They are extremely thin, much like a traditional barcode. As a result, manufacturers can easily apply them to furniture, clothing, packaging and more.

While both RFID tags and barcodes are effective for inventory management, barcodes are the better choice for SMBs. Not only are they widely accepted across most business sectors, but they are more affordable for SMBs that need to cut costs. The barcodes themselves are cheaper than RFID tags, along with the software used to decipher, interpret and use the product data. Barcode readers also tend to be cheaper and less complex than RFID readers. As they are easier to use, employees will prefer scanning barcode to RFID tags, directly increasing productivity and workplace morale.

How do barcodes cut costs and improve efficiency?

Human error is one of the main reasons companies choose to adopt barcode technology. Instead of manually looking for or entering product data, employees simply scan the label, sending the product's information to the company's inventory system. Instead of manually writing down all the stock an SMB has, employees can walk through a warehouse, scanning each product in a relatively short amount of time.

As stated previously, barcode labels are affordable to print, making them smart and cheap investments for cash-strapped SMBs. Furthermore, with the embedded tracking capabilities of most innovative barcode labels, SMBs no longer have to suffer customer fallout related to damaged or missing products, which directly impacts profit margins. Choosing barcodes means boosting revenue and efficiency.

At Stranco, we offer a wide selection of thermal transfer barcode labels for small to medium-sized manufacturers seeking out ways to cut costs and gain profits. With no minimum order requirements, SMBs can order as many or as few labels as they want to fulfill their unique labeling needs. Contact one of our customer service representatives today to learn more!